Check out our latest news as well as finding useful tips and resources.

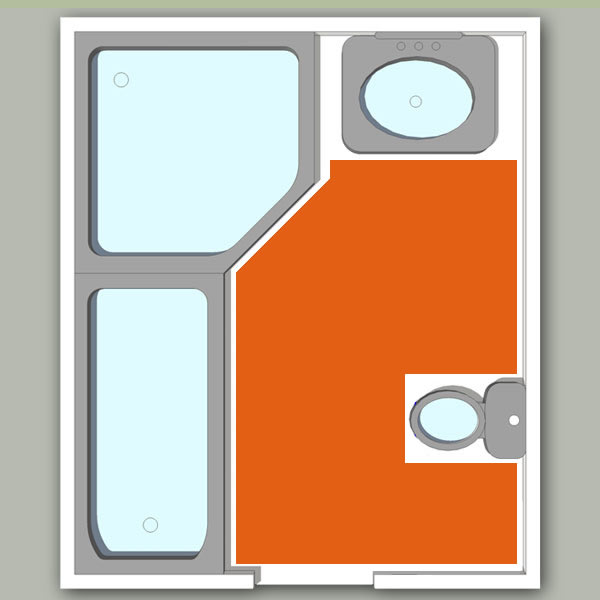

The heating area is calculated as above. The room area minus the space for permanent fixtures and the relevant insets.

With cable kits the spacing between the rows of cable is also of consequence. The standard spacing is 100mm. For most installations, this will be adequate for average heating output. Where more heat output is required this row spacing can be decreased resulting in more cable per square meter and thus more heat output. Equally the larger the spacing employed means less cable required and so a lower heat output is generated. Our kit roll lengths and area coverage in the online store are based on the standard spacing.

To calculate the length of cable required apply this formula where

Cable Length (m) = Heating area (m²) x1000 / Spacing Distance (mm).

If you had a heating area of 12.3m² and a standard spacing distance of 100mm the required cable length would be 123 meters (12300/100). You would, therefore, choose a kit that is nearest to but BELOW the required cable length of 123 meters (you do not cut the cable). The Coldbuster Screed kit, in this case, would be the 120m cable length. We have provided a calculator for you below.

The same principle applies to Coldbuster mat kits as cable kits in calculating the heating area. You only need to measure the area you walk on to determine your heating area. So baths, vanity units, toilets areas are not included as well as Kitchen units and cupboard areas or similar permanent fixtures in Living Rooms and Bedrooms. Similarly, the mat need the same insets of 150mm away from walls and fixtures, 300mm from drains and 500mm from other heat sources. If you need any help in regard to measuring your heating area you can send us your plans or give us a call for our free support service.

The big difference to cable kits is that the spacing between the rows of cable is fixed and so does not come into any calculations. The Kits are provided to fit predetermined heating areas. You simply calculate your heating area and choose the closest size of kit that is below that value. You have to choose the kit that is below the heating area dimension because, like the cable kits, you can not cut the cable. The rolls have a single cold tail heating element. This means that you now do not need to return to the starting point to connect back to the thermostat. You simply lay out the mesh roll to the end of the run and just connect the lead at the starting point. Simple, quick responsive heat, cost-effective solution for any room and floor surface.

The simplest way to get the right product and the right size of product is to Get A Free Quote

Need Electric Underfloor Heating?

For more information see our Measuring Up for Floor Heating Guide

Key Factors Affecting the Running Costs of Electric Floor Heating from Coldbuster

There are many factors and assumptions that may influence the costs of running electric floor heating.

Please note that the factors and the assumptions that underpin this Running Cost Calculator mean that results should only be used as a rough guide, as conditions (some of which are listed below) can vary greatly.

The efficiency and cost of the electricity used for heating directly impact running costs. More efficient energy sources and favourable electricity tariffs reduce overall expenses. Electricity prices vary by provider and plan. Choosing an energy-efficient tariff and monitoring peak and off-peak rates can help minimise heating costs.

The assumption in this running cost estimate model is that your energy source is cost-effective and the electricity tariff is optimised for heating needs.

The total time the heating system is operational impacts energy consumption. Running the system only when necessary and using programmable thermostats to create heating schedules can optimise usage.

The assumption in this running cost estimate model is that your heating is running only when necessary and optimised accordingly.

A duty cycle for electric underfloor heating represents the percentage of time the system is actively heating versus its total operational time. After the floor reaches its set temperature, the system cycles on and off to maintain it. The calculator factors this in and assumes a 50% duty cycle.

The temperature set on the thermostat directly affects energy usage. Lowering the thermostat temperature by just a few degrees can significantly reduce running costs without compromising comfort. Programmable and smart thermostats can optimise heating schedules, reducing energy use during non-peak times and enhancing overall efficiency. Setting the thermostat to an optimal temperature (e.g., 20-22°C) during occupied times and lowering it (or even better turning it off) when not in use can significantly affect running costs.

The assumption in this running cost estimate model is that you are using one of Coldbuster’s smart programmable thermostats to manage heating schedules effectively and that the settings are optimised for both comfort and efficiency.

Proper insulation reduces heat loss, making the heating system more efficient. Effective insulation in your floors, walls and roofs will help maintain the desired temperature with less energy consumption. Better insulation helps retain heat within the room, minimising the energy required to maintain comfort.

The assumption in this running cost estimate model is that your building has high-quality insulation materials installed in the walls, roof, and floor.

The type of floor substrate affects heat retention and energy efficiency. Concrete floors, for example, retain heat longer, while timber floors may require more energy to maintain warmth.

The assumption is that your floor substrate is conducive to efficient heating, with thermal insulation boards used where necessary to enhance heat retention.

Different floor coverings have varying thermal properties. Materials like tile and stone conduct heat efficiently, while carpets and wood may require higher energy to achieve the same comfort level.

The assumption in this running cost estimate model is that your flooring material is chosen with consideration of its thermal conductivity and compatibility with the heating system.

Draughts from poorly sealed windows and doors, as well as other gaps, can lead to heat loss and increased energy consumption. The type and quality of windows and doors significantly impact heat loss and gain. Double-glazing and well-sealed frames reduce draughts and improve thermal efficiency.

The assumption in this running cost estimate model is that your windows, doors, and other potential gaps are well-sealed to prevent drafts and heat loss.

The overall energy efficiency of a building, including factors like construction quality, age, design and energy ratings, all affect its thermal efficiency and hence impacts heating costs. Older buildings may have more heat loss compared to newer, energy-efficient constructions.

The assumption in this running cost estimate model is that your building is relatively modern or has been updated to meet contemporary energy efficiency standards.

The local climate influences heating needs. Colder outdoor temperatures increase the demand for indoor heating. Regions with milder winters require less heating and would therefore typically have lower running costs compared to areas with harsh winter and cold conditions.

The assumption in this running cost estimate model is based on average climatic conditions specific to the region in Australia where you are located and where the system is installed.

The efficiency of the underfloor heating system itself plays a crucial role. The efficiency determines how effectively it converts electrical energy into heat. Modern systems with advanced controls and high efficiency like Coldbuster use less energy to achieve the desired warmth.

The assumption in this running cost estimate model is that your heating system is running efficiently at all times.

The ability to control heating in different zones or rooms independently allows for more precise energy use, heating only the areas that need it.

The assumption in this running cost estimate model is that your heating system is designed with zoning capabilities for customised temperature control.

The design of the heating system, including the layout, spacing, and type of heating elements, affects heat distribution and overall efficiency. The size of the room in relation to the heater’s capacity is crucial. An appropriately sized heater ensures efficient heating without overworking the system.

The assumption in this running cost estimate model is that your heating system is designed and installed by experienced Coldbuster installation professionals or other suitably qualified professionals to ensure optimal performance and energy efficiency.

Consistent and predictable usage patterns help in planning and optimising energy consumption. Irregular or excessive use can lead to higher costs.

The assumption in this running cost estimate model is that your usage patterns are regular and not excessive.

Higher ceilings result in larger volumes of air to heat, which can increase energy consumption. Rooms with standard ceiling heights are more energy efficient.

The assumption in this running cost estimate model is that your ceiling heights are standard (2.4 to 2.7 meters) to maintain optimal energy efficiency and minimize excess energy use.